work instructions

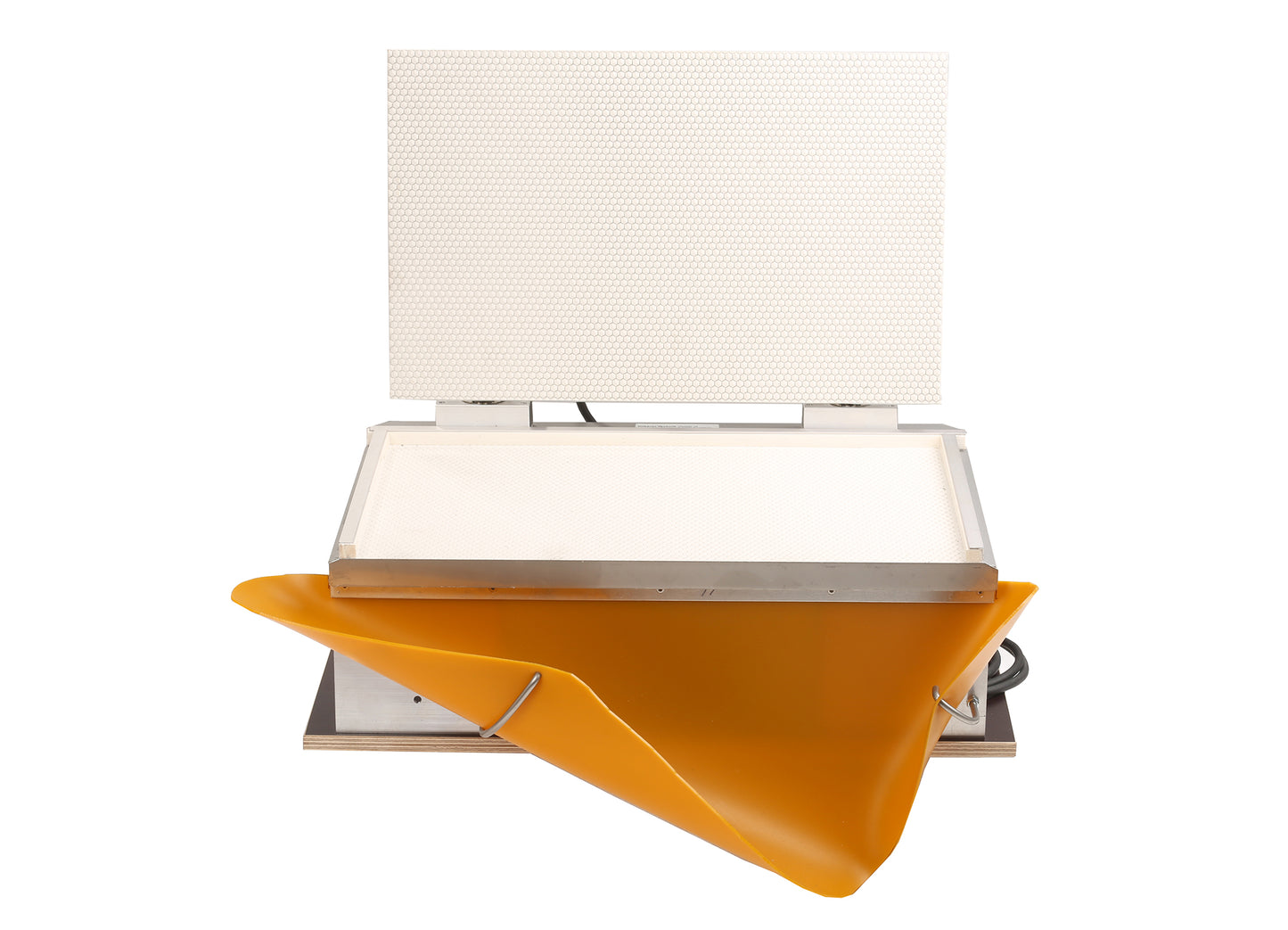

To ensure that the foundation comes off the mold easily, take some spirit in a standard spray bottle and spray it lightly onto the silicone mold before each pouring process. This will make the foundation come off even easier.

Regarding the wax: it should not get too hot, the best option is an electrically heated preserving pot (15 liters) with a thermostat (temperature approx. 80 - 85 °C). To pour the wax into the mold, it is best to use a 0.7-liter ladle with a pouring spout, then you can fill the mold completely with wax in one go, excess wax flows back into the melting pot and therefore does not need to be liquefied again.

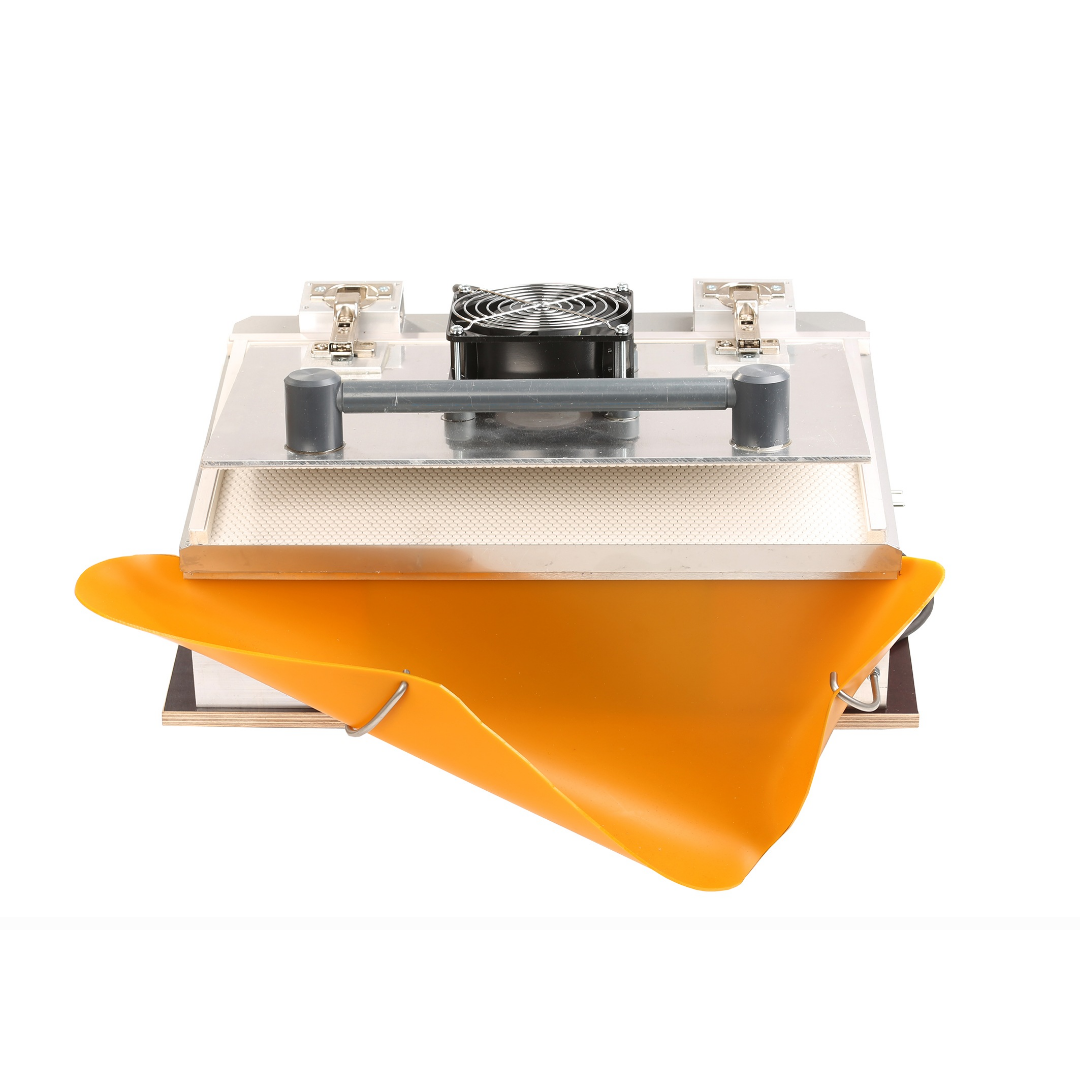

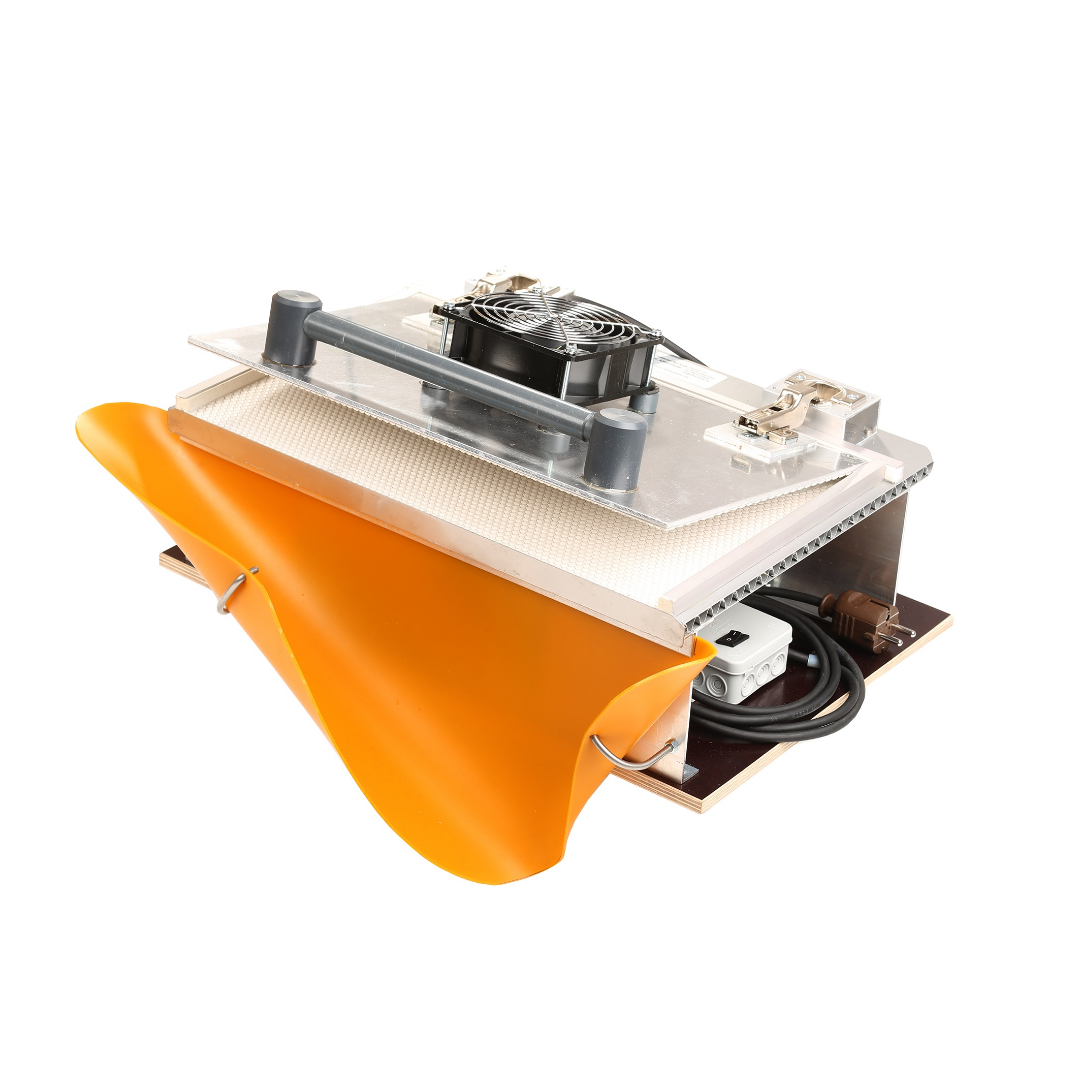

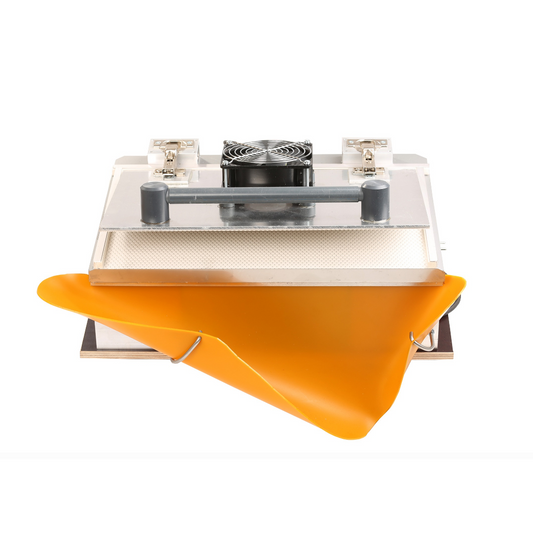

And another special feature: The thickness of the middle walls can be changed by turning the adjusting screws on the hinges and applying the appropriate pressure when closing the mold.

With the help of the compressed air gun, the foundation sheets can be removed practically without contact, meaning that the foundation sheets are not bent when removed.

The molds can be manufactured in all common center wall dimensions up to 426 mm long and 300 mm high.

Advantages of the air-cooled mold: Short set-up times, no water consumption, energy-saving because the excess wax does not have to be re-melted, wax runs directly back into the melting pot, so there is no water in the wax, no holes in the foundation walls and no drip marks on the work table, 100% yield, the honeycombs remain smooth and even when removed, the thickness of the foundation walls is adjustable. The lower support plate consists of an aluminum hollow profile with high thermal conductivity. Air flows constantly through the hollow ribs, which means very short cooling times are achieved.

Affordable price, the molds are about 30% cheaper than the water-cooled molds.

The molds are of very high quality, the surface is very smooth because no welding is used during production.